Working principle editing broadcast

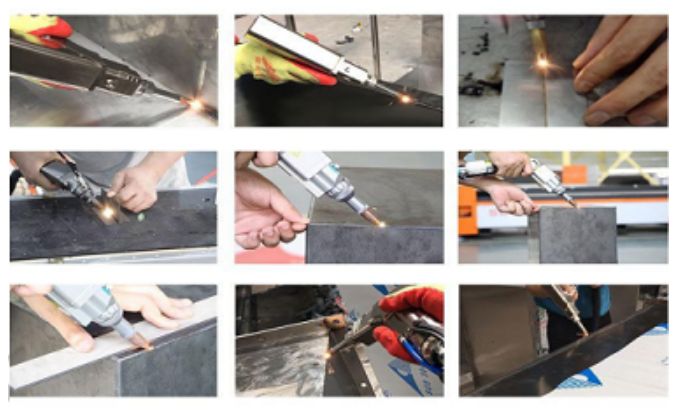

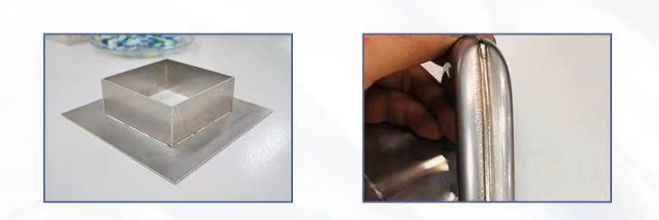

Laser welding is to use high -energy laser pulses to perform local heating in the micro area with high -energy laser pulses. The energy of laser radiation is performed by melting the material through the internal diffusion of the thermal guide material to form a specific melting pool. It is a new type of welding method. It is mainly aimed at the welding of thin -walled materials and precision parts. It can realize point welding, connecting welding, stacked welding, sealing welding, etc. The deep ratio is high, the weld width is small, the heat affects the area is small, and the heat affects the area is small. Small deformation, fast welding speed, flat welding seams and aesthetics, no treatment after welding or simply processing, high weld quality, no pores, accurate control, small light points, high positioning accuracy, and easy to achieve automation.

Features

In fact, there will be very good sales for this type of welding equipment, which has a lot to do with its characteristics, and these characteristics are generally reflected in the following aspects.

In fact, there will be very good sales for this type of welding equipment, which has a lot to do with its characteristics, and these characteristics are generally reflected in the following aspects.Application

Sanitary ware in the field of bathroom sanitary ware, welding welding welding of water pipes, transformer connections, three -way, gate valves, and shower shower. Glasses production industry: high -precision welding welding of stainless steel plates, aluminum alloy and other materials such as the structure, border and other parts of the frame. Hardware industry: centrifugal impeller, teapot, door handle, etc., welding welding of complicated hardware stamping parts, cast iron parts. Automobile manufacturing: car engine cylinder pads, hydraulic presses tall tingle welding, car spark plug welding welding, filter element welding welding, etc. The medical device industry: medical equipment, medical machinery stainless steel plate voltage sealing parts, and welding welding of components. Electronic industry: sealing welding in the middle relay, welding welding of connectors connectors, and welding welding of plastic shells such as mobile phones and MP3 and components. The electric welding welding of the motor shell and the connected line, the optical fiber adapter connector. Family hardware, kitchen supplies, bathroom sanitary ware, stainless steel plate door pull hands, electronic components, sensors, clocks, precision machinery, communication, art and other fields, vehicle hydraulic machines and other high -pressure resistance in the field Welding these.Laser welding host

Parameter

| Model | EC-1500/2000 |

| Laser power | 1500W/2000W |

| Laser wavelength | 1080nm 1064nm±5nm |

| Laser mode | Single mode |

| Photoelectric conversion efficiency | 30% |

| Work type | continuous |

| Fiber length | 10m |

| Cooling type | Water cooling |

| Cooler model | 1500W /2000W |

| Cooling water temperature | 20-25℃ |

| Power supply | AC220 AC380±10%,50/60Hz |

| Working temperature | 10~35℃ |

| Working environment humidity | ≤95% |

| Power adjustment range | 5-95% |

| Power instability | ≤2% |

| Transmission fiber core diameter | 25um-50um |

Complete accessories

The whole machine includes the following components: welding machine, wire feeder, argon gas meter, goggles, hexagonal tools, gloves, supporting nozzle, protective lens.

| Part name | Quantity(set) | Brand name |

| Laser device | 1 |

|

| Laser head | 1 |

|

| Dual temperature dual control chiller | 1 |

|

| Power switch button | 4 | Yijia |

| Electromagnetic valve | 1 | Yadeke |

| AC contactor | 2 | Zhengtai |

| Master switch | 1 | Delixi |

The overall warranty of the welding machine is one year except for the cabinet. Laser lenses, welding torch lenses, and copper nozzles are vulnerable parts and are not covered by the warranty.