Product Description

Features of UV laser marking machine model

Product parameters

| Product name | Uv laser marking machine |

| Laser power | 3w /5w /10w |

| Laser use life | 10000 hours (the actual life depends on the requirements and the use environment) |

| Laser wavelength | 355nm |

| Average output power | 0-3W continuously adjustable, optional: 0-5W/0-10W continuously adjustable |

| Modulation frequency range | 10kHz-200kHz |

| Beam quality | M2<1.1 |

| Linear velocity of galvanometer | < 12000mm/s |

| Mark character | speed 300 characters//Roman font, word height 1mm |

| Repetitive marking accuracy | ± 0.003mm |

| Marking line width | < 0012mm |

| Character height | 0.15mm |

| Marking depth | < 0.2mm (depending on the specific model and material) |

| Marking area | 110 * 110mm |

| Working focal length | 163 ± 2mm |

| Cooling mode | water cooling |

| Rated power | ≤ 1kW |

| Laser voltage | ≤ 1kW |

| Laser voltage | 220V/single-phase/50Hz/10A |

| Environmental requirements | - 5~45 ° C; Humidity<90% |

Advantages of UV marking machine

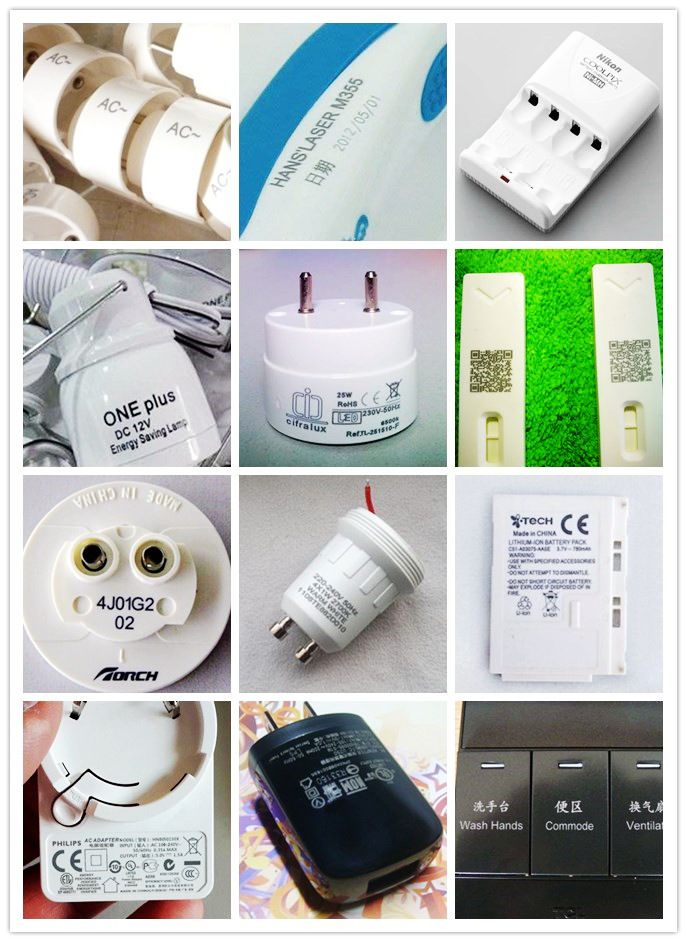

Generally speaking, our traditional laser marking machine (optical fiber laser marking machine, co2 laser marking machine) mainly uses the thermal effect of laser to burn the material surface to form a color change or vaporize the material surface layer to leak the underlying material to form a mark. However, this mark formed by thermal effect has great defects in the soft film packaging industry. Carbon dioxide hitting the soft film will easily cause the soft film to break down and leak, thus affecting the shelf life of food. There is no response when the optical fiber laser hits many plastic films, and the focal depth of the optical fiber (only one millimeter) is easy to be illegible when the bag shakes or warps. The appearance of purple light perfectly solves the above problems. The ultraviolet laser marking machine uses 355 nm short wavelength ultraviolet laser, which is very good for soft film absorption. The principle of ultraviolet laser marking machine is that 355 nm ultraviolet light irradiates the coating on the surface of the soft film, causing chemical changes in the layer, thus producing color changes. Because ultraviolet light only reacts with the coating, it will not break through the soft film packaging.Sample Show

Application: UV laser marking machine is widely used. Used for ultra-fine marking and carving, especially for food and medicine bags Application industries such as marking of packaging materials, drilling of holes, high-speed division of glass materials and complex graphic cutting of silicon wafers. Pcb board marking and scribing; Microhole and blind hole processing of silicon wafer; LCD LCD glass two-dimensional code marking, glassware surface punching, metal surface coating marking, plastic keys, electronic components, gifts, communication equipment, building materials, etc. The most widely used in the ordinary industry is to break glass.